Introduction:

In the fast-paced realm of electronics, where innovation is a constant, the heart of every electronic device lies in its Printed Circuit Board (PCB). As technology advances, so does the demand for more intricate and compact electronic components. This demand has given rise to a fascinating world of precision engineering – the world of PCB assembly machines. In this blog, we will delve into the cutting-edge technologies that power these machines and explore how they play a pivotal role in shaping the electronic landscape.

The Evolution of PCB Assembly Machines:

The journey of PCB assembly machines can be traced back to the manual soldering processes of the past. However, as the complexity of electronic devices increased, so did the need for more efficient and precise assembly methods. This led to the development of automated PCB assembly machines, marking a significant leap forward in manufacturing capabilities.

Today, these machines have evolved into sophisticated systems that integrate advanced technologies such as Artificial Intelligence (AI), machine learning, and robotics. These innovations have not only accelerated the production process but have also elevated the precision and quality of PCB assembly to unprecedented levels.

Precision at its Core:

Precision is the cornerstone of PCB assembly, and modern machines are designed to achieve levels of accuracy that were once deemed unattainable. Surface Mount Technology (SMT) machines, for example, utilize high-speed cameras and laser-guided placement systems to accurately position components on the PCB with microscopic precision. This level of accuracy is crucial in meeting the demands of miniaturized electronic devices, where even the tiniest error can lead to malfunctions.

The Integration of Artificial Intelligence:

Artificial Intelligence has emerged as a game-changer in the world of PCB assembly. Machine learning algorithms are employed to optimize the assembly process by analyzing vast amounts of data in real-time. These algorithms can identify patterns, predict potential issues, and dynamically adjust parameters to ensure optimal performance. This not only enhances efficiency but also reduces the risk of defects, ultimately leading to higher yields and lower production costs.

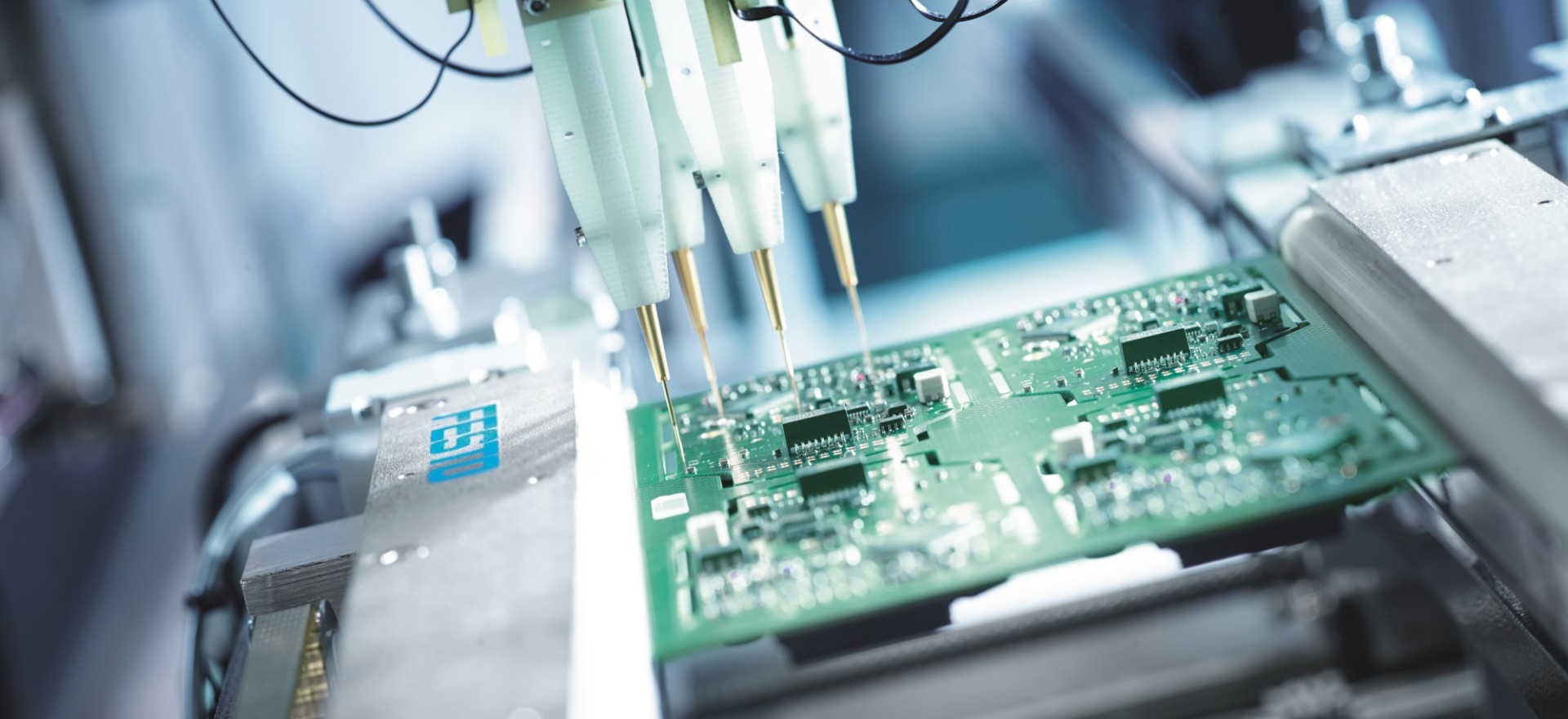

Robotic Revolution:

Robotic arms have become integral components of modern PCB assembly machines. These highly versatile robots can perform intricate tasks with speed and precision, such as picking and placing components, soldering, and quality control. The use of robotics not only streamlines the assembly process but also minimizes the risk of human error, contributing to the overall reliability of electronic devices.

Challenges and Future Outlook:

While the current state of PCB assembly machines is impressive, the industry continues to face challenges. As electronic devices become more complex and the demand for smaller, more powerful components increases, there is a constant need for innovation. Researchers and engineers are exploring new materials, refining existing technologies, and pushing the boundaries of what is possible.

Looking ahead, the future promises even more exciting developments. The integration of nanotechnology, 3D printing, and advanced materials is expected to further revolutionize PCB assembly, opening doors to unprecedented levels of miniaturization and functionality.

Conclusion:

In the dynamic world of electronics, PCB assembly machines stand as the unsung heroes, tirelessly working behind the scenes to bring our gadgets to life. The precision unleashed by these cutting-edge machines is not just a testament to technological prowess but a driving force that propels the electronic industry forward. As we continue to witness the evolution of PCB assembly technologies, one thing remains clear – the journey towards smaller, faster, and more powerful electronic devices is intricately woven with the threads of precision unleashed by these remarkable machines.