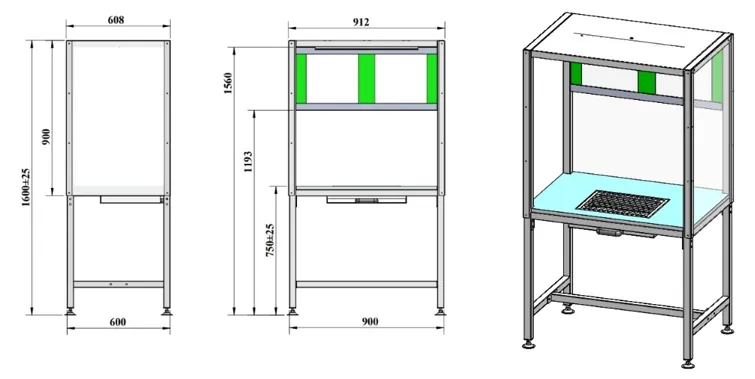

Table for Lead Cutting

A customised work station for manual post solder lead cutting

After the PCB is soldered, the excess legs need to be trimmed. A popular method in the industry is to cut the leads manually, using manual or pneumatic cutters. During the cutting operation, the cut leads fly of to nearby areas, thereby making the space untidy and even has a safety concern, which may cause eye injury to the workers in the nearby area.

At Yontro we have developed a work table which is covered from all sides, except from the place where the operator works, thereby preventing the cut leads from flying off to adjoining areas.

The table also has a wire mesh top and a tray beneath, to facilitate, collecting the cut leads.