Low Cost Soldering Equipment

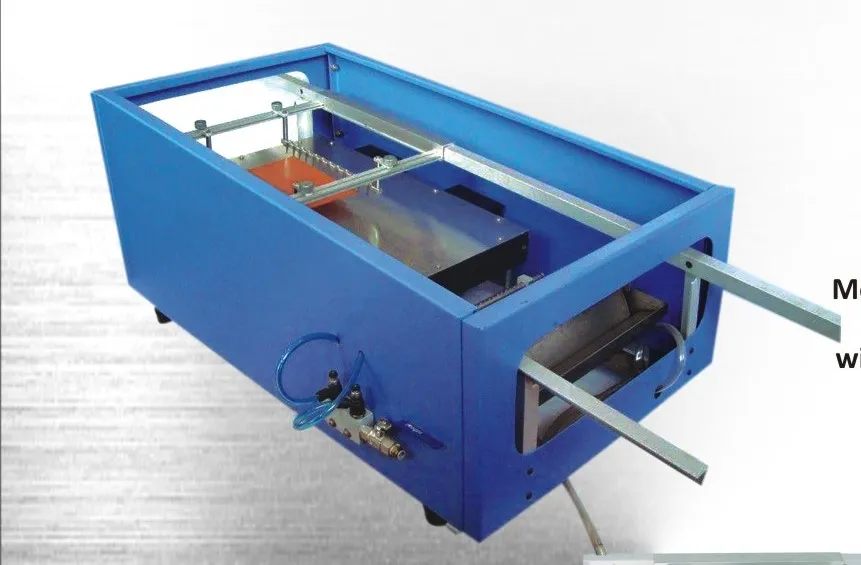

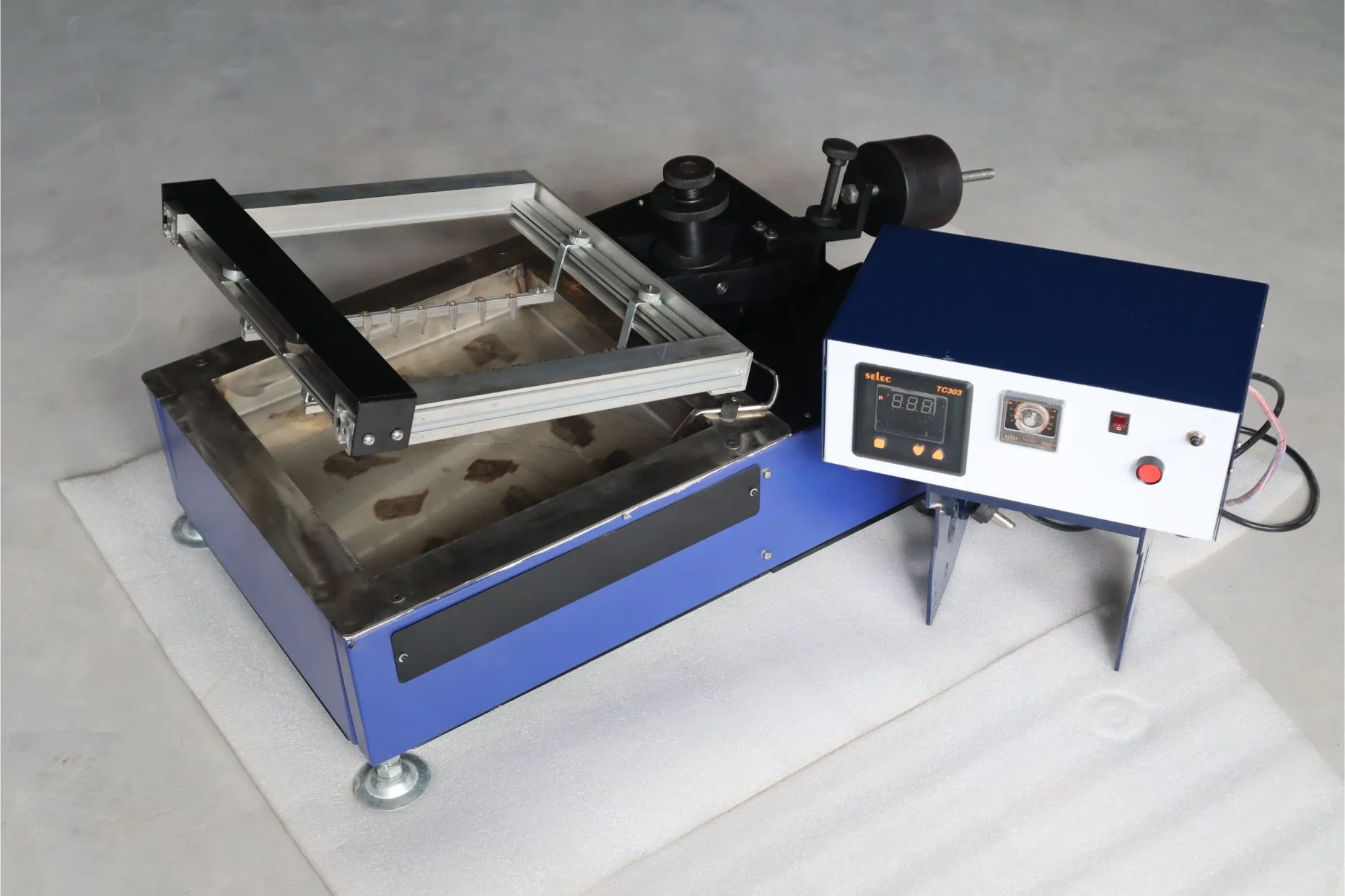

Model : FFP 915

Foam Fluxer with Pre-Heater

This machine is to be used along with the Dip Soldering Machine. For obtaining a reliable solder joint, the PBA needs to be properly fluxed, and pre- heated. This machine is used for fluxing the PCB using a foam fluxer, an air knife for removing the excess flux and the pre heater unit for activating the flux so that the leads and the PCB to be soldered are free of oxides and contamination. Completion of this process ensures a good and reliable solder joint during the dip soldering process.