Low Cost Soldering Equipment

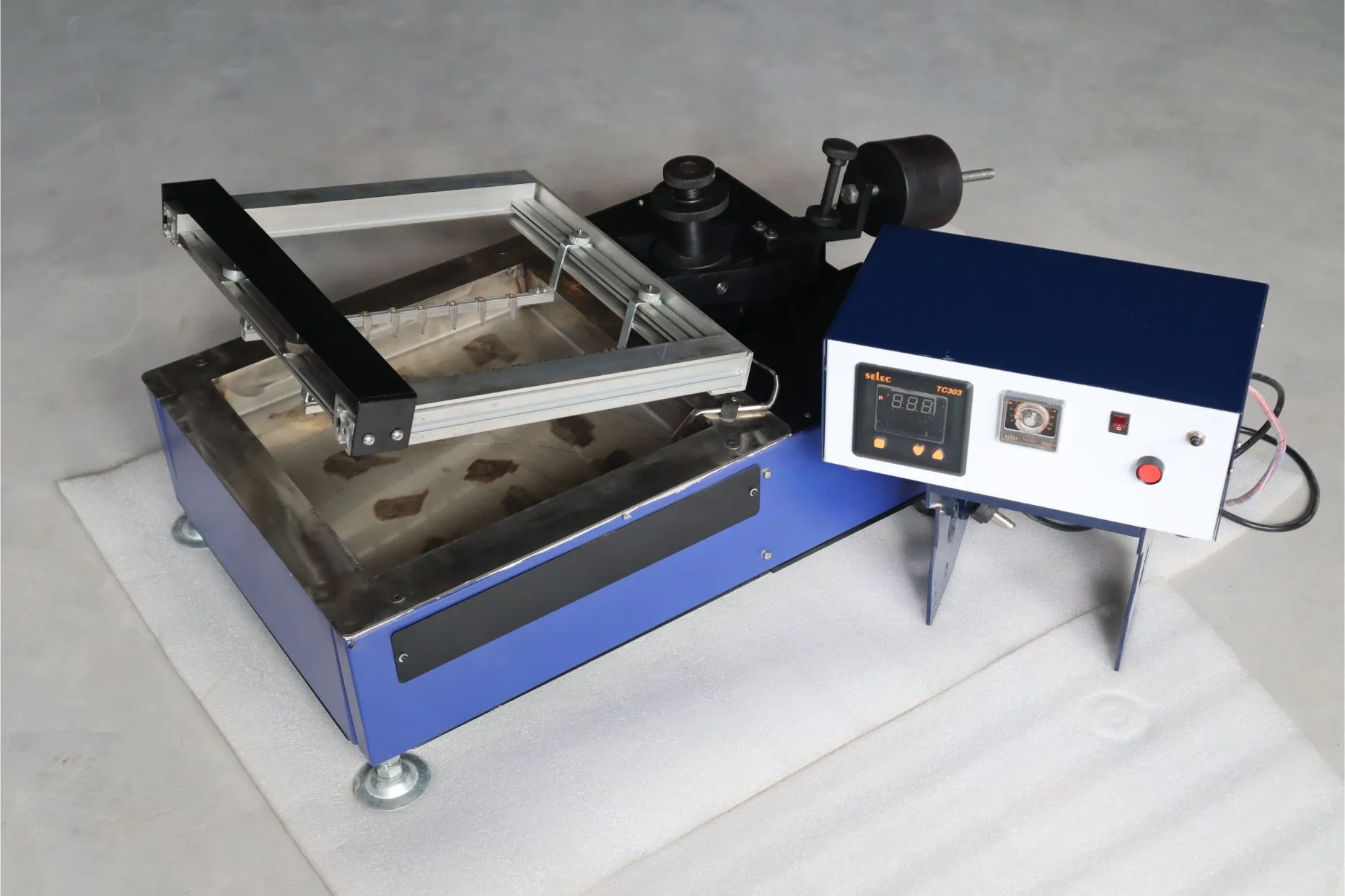

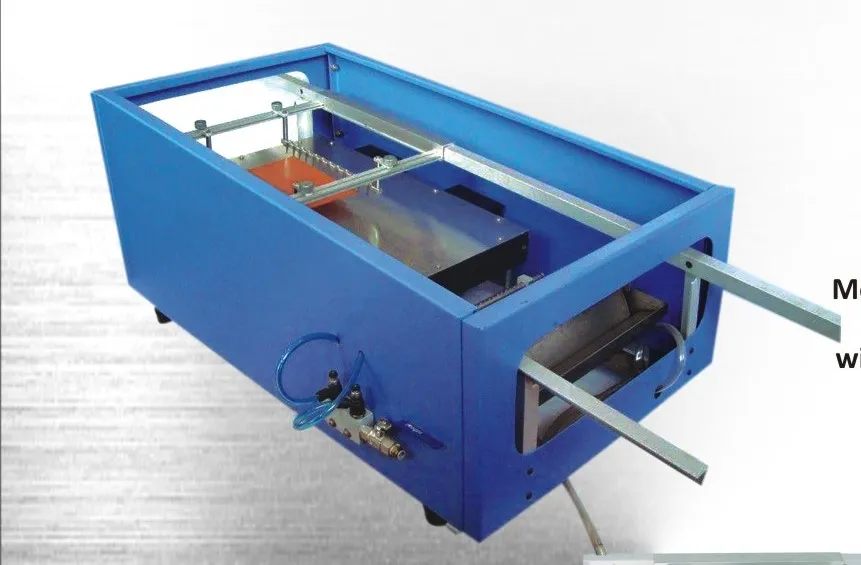

Model : DIP 905

Automatic Dip Soldering Machine

The Dip soldering machine is a low cost solution for mass soldering of leads to the PCB’s. It is suitable for through hole components and can be used for single sided as well as PTH boards.

A contamination free, SS bath is used. Plate type heating elements are used which are attached to the outer side of the base of the solder bath. Unlike other make solder baths they are not submerged in the solder, thereby ensuring easy replacement of heater in the event of its failure.

A specially designed motor driven cam, which lowers the PCB on the bath and retracts it, ensures a smooth peel back, thereby ensuring good and reliable solder joints.