Wave Solidering Machine — Finger Conveyor

MODEL WSM 350 FC LF

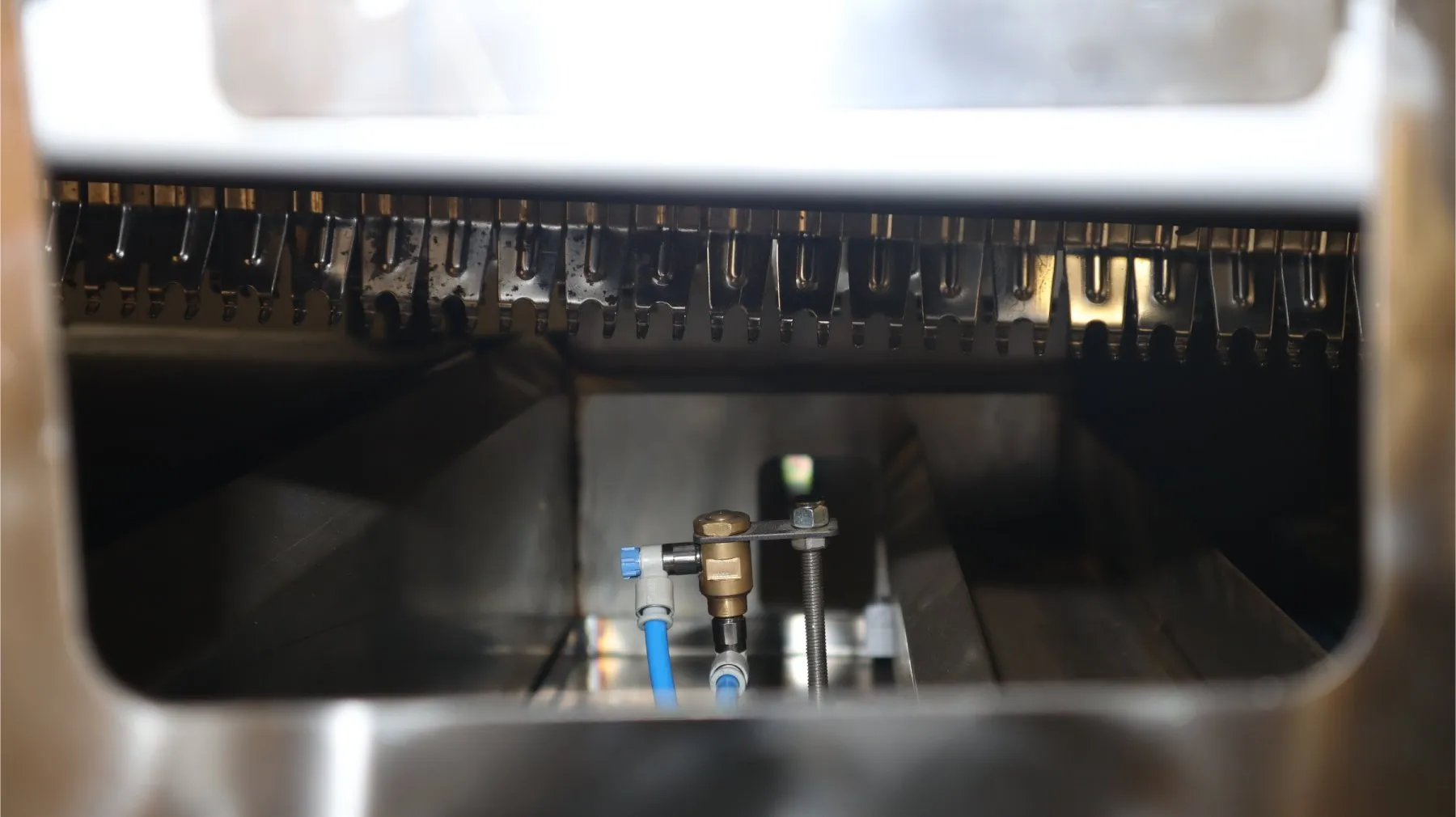

This machine has been developed for high production assembly lines. In this machine the PCB’s are transported directly from the MI line, into the machine through an input conveyor. Thereby eliminating time loss on account of manually transferring the PCB from the MI Line to the Soldering Machine. Similarly at the output of the machine, the PCB can be unloaded onto a cooling conveyor and further transported to the belt of the touch-up line.

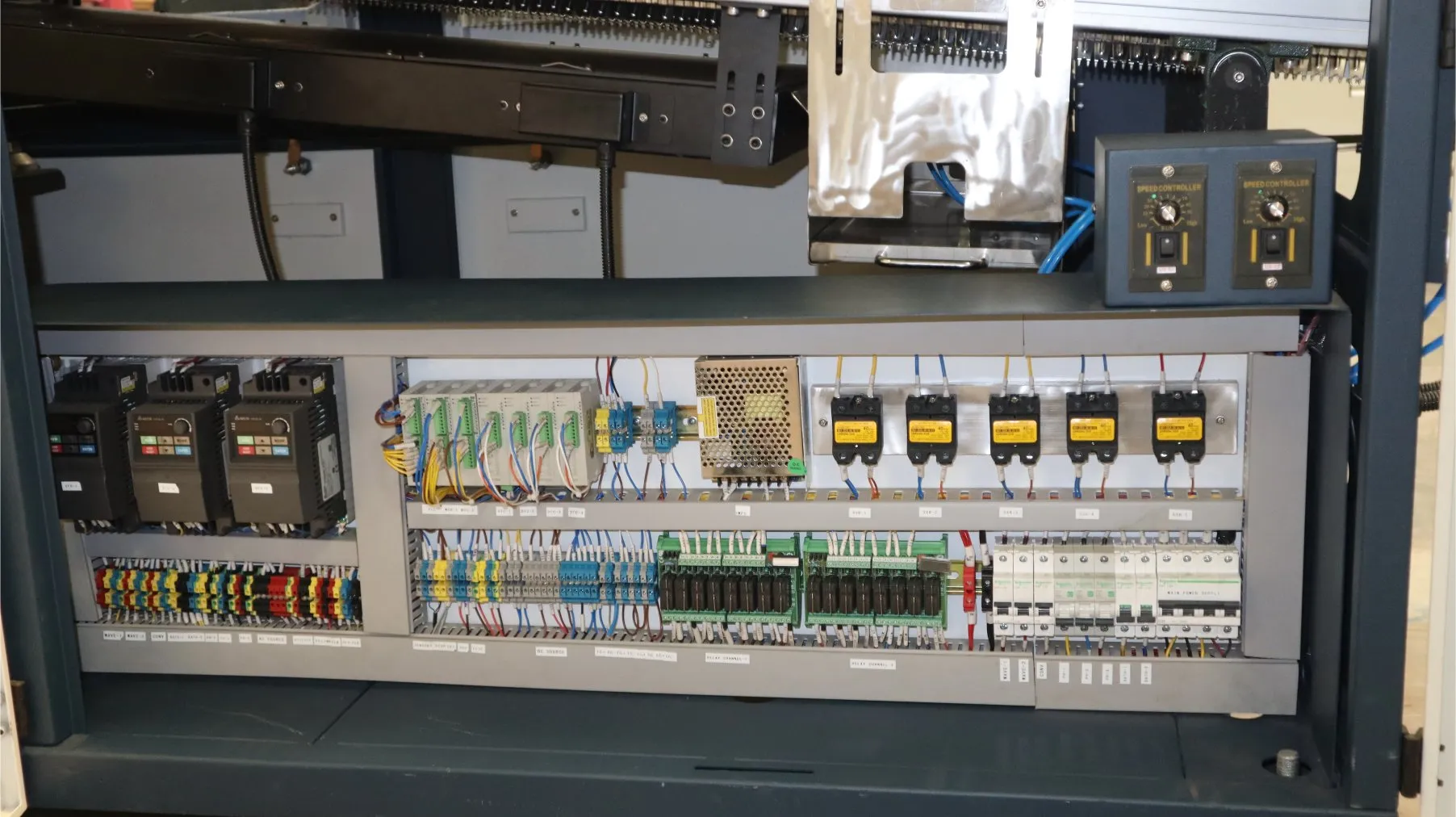

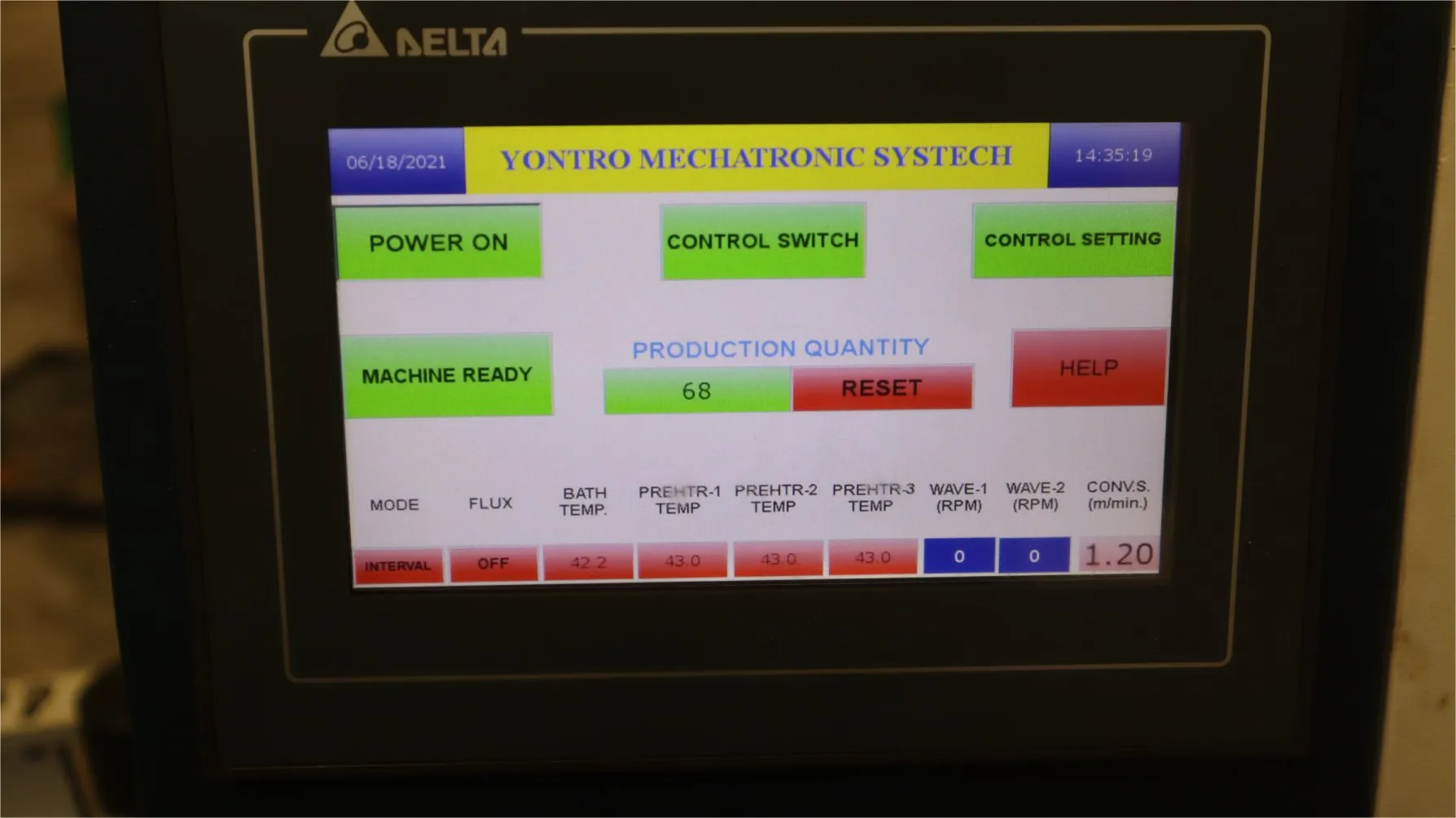

The machine is controlled through a HMI (Touch screen) + PLC control. It has option of both spray fluxer or the foam fluxer. The solder pot also has an option for working with Lead free or leaded solder.

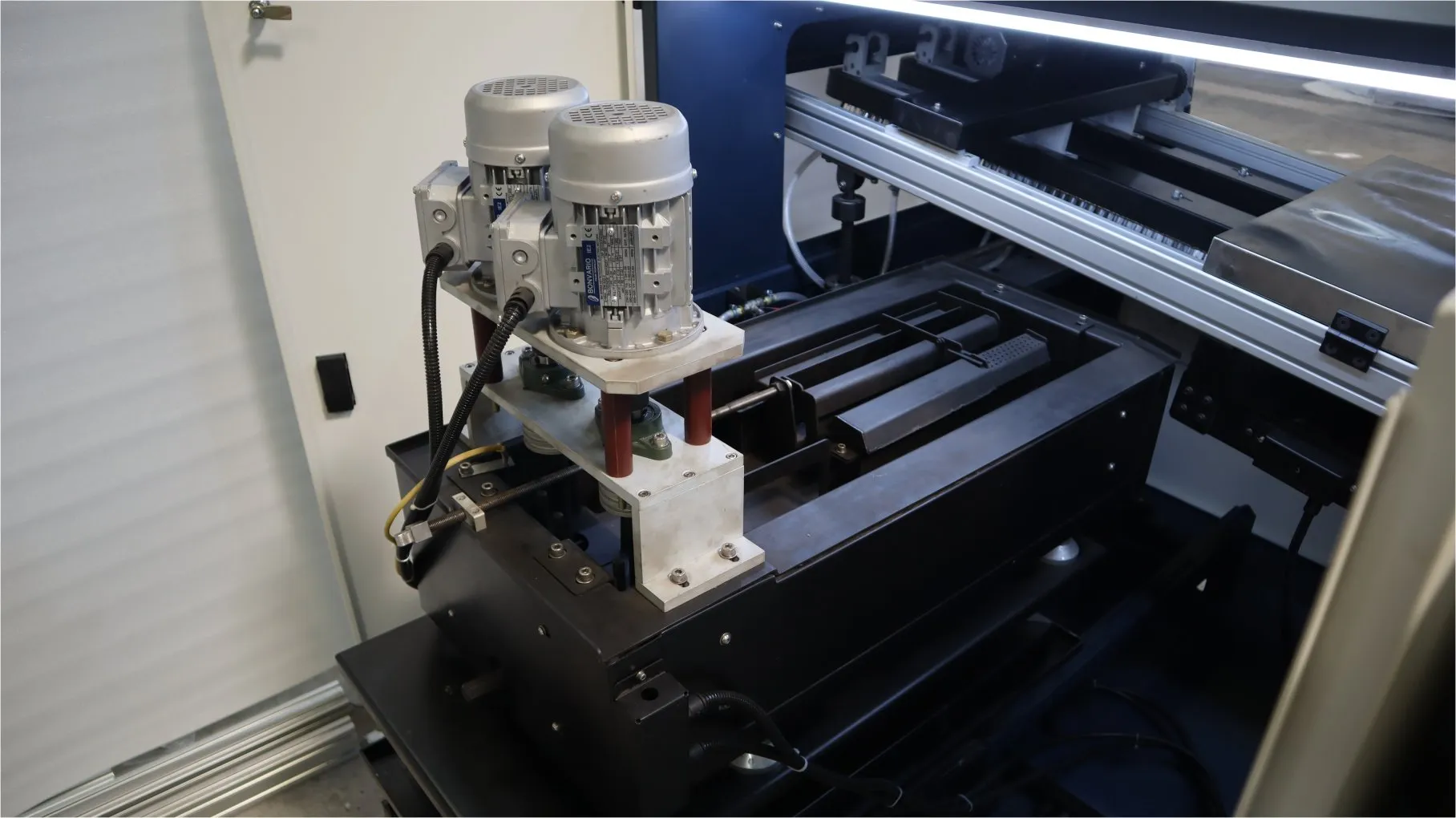

The machine incorporates a dual wave bath making it suitable for soldering both through hole and SMD components.