Motorised Free Flow Conveyor

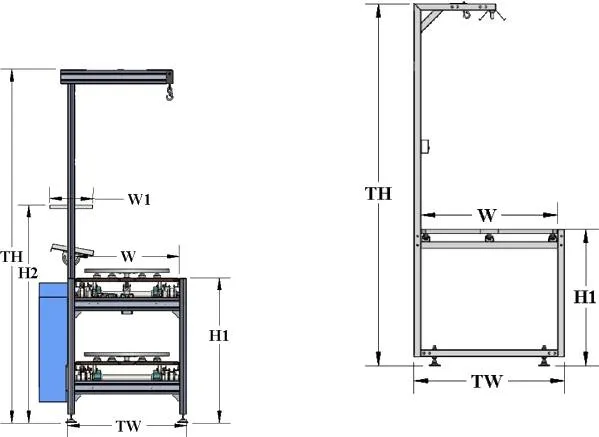

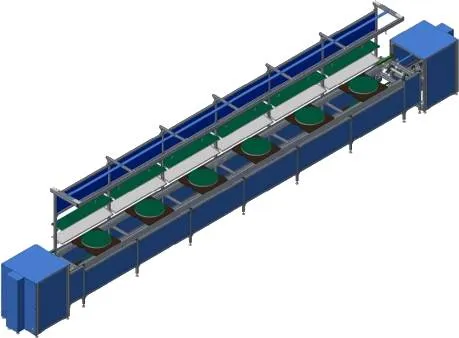

This type of conveyor is used for final assembly of products or box building. In this the part to be assembled is placed on a pallet and the assembly is done on the conveyor itself. It is a motorised conveyor and the pallet is automatically transferred from one station to the other.

This type of conveyor is used for final assembly of products. The part to be assembled is placed on a pallet made of wooden board. The side edges of the pallet is placed on a pair of triple speed chain running continuously on a specially extruded heavy duty aluminium profile. This moves the pallet from one station to the next. At each station the pallet is stopped with a pneumatic stopper. The operator completes the assembly job that has been assigned to him, and releases the stopper, so that the pallet moves on to the next station. This type of conveyor is used for assembly of heavier appliances like TV, AC, refrigerator, water cooler, inverter, UPS etc.