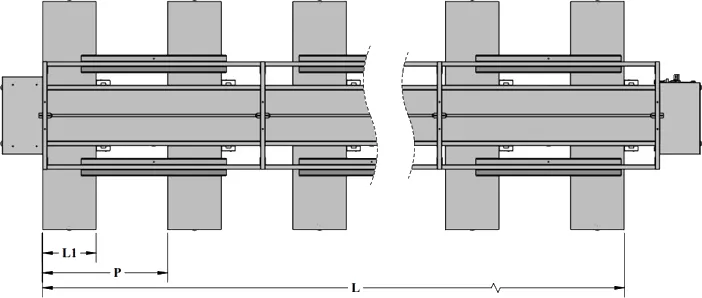

| Belt Width |

400 mm |

100 mm to 1800 mm

In multiples of 50 mm

|

| Conveyor Length |

As per user requirement |

| Belt Type |

Option of PVC / PU / ESD / Rough Top or Super Grip |

| Belt Thickness |

2.0 / 3.0 / 4.0 / 5.0 mm |

| Belt Support on Top |

Powder coated MS Panel |

SS panel / Roller bed |

| Best Support Bottom |

Rollers at a distance of 1800 mm |

Rollers as per design requirement |

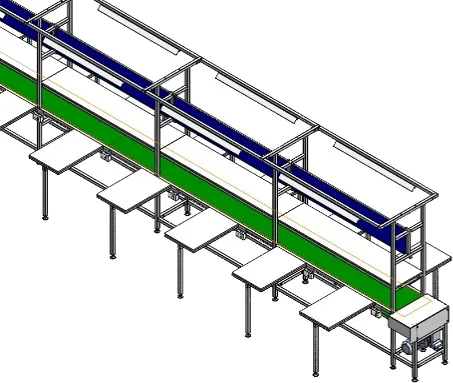

| Structure |

Powder coated MS pipe frame |

SS frame / Anodized Al profile |

| Conveyor Speed |

Fixed or Variable as per user requirement |

| Working Height |

750 mm |

900 mm OR As per user requirement |

| Total Height |

2000 mm |

As per user requirement |

| Height adjustment |

+/- 50 mm |

As per user requirement |

| Ht. Adj. Method |

Through Levelling Feet |

Through bracket or other arrangement |

| Side Working Platform Parallel to Belt |

• Width 300 mm

• Laminated Board (White)

|

• Wooden Board with ESD/PVC mat

• SS Sheet Metal Panel

• Powder coated MS Panel

|

| Independent Working Platform Perpendicular to Belt |

• Size-As per requirement

• Laminated Board (White)

|

• Wooden Board with ESD/PVC mat

• SS Sheet Metal Panel

• Powder coated MS Panel

|

| Shelf above Belt |

Provided of Laminated Board (White Laminate)

|

• Not Required

• Wooden Board with ESD/ PVC Mat

• SS Sheet Metal Panel

• Powder coated MS Panel

|

| Display Board |

Acrylic Sheet

( Green)

|

• Pin Board with colour of your choice

• White Board

• Magnetic Board

|

| Lighting |

We provide sheet metal reflectors one per 6 feet module on both side of belt |

• LED Tube light one at every 6 feet module on both side of belt

• Qty of lights as per your requirement

|

| Power Socket |

Provided on request with following information :

• Combination of Socket & Switch required per board with current specification

• Number of power board per 6 feet module

• Placement of the Power board

|

| Pneumatic Line |

Provided on request with following information :

• Number of outlets per 6 feet module

• Output Required by QRC or Ball Valve

• Placement of Line above the top post or beneath the belt

|

| Fume Exhaust Pipe Line |

Provided on request with following information :

• Number of exhaust outlets per 6 feet module

• Inline Fans – Imported or Yontro Make

• Standardly one Inline fan is provided per 12 feet length

|

| Other Optional |

• Tool Slider for Spring Balancer on Top Post

• Sensor for start / stop

• Partition above belt

• Wall Fan on Top Post

|

• Cable Tray

• Bin Rail

• Bottle Holder

• Dustbin Holder

• Drawer Cabinet

|

|

ITEM INFORMATION TO BE PROVIDED

|

• Item to moved

• Weight of one unit

• Total weight on conveyor

|

• Product to be stopped / dropped at the end of conveyor or to be transferred to another conveyor

|