Manual Double Sided MI Line

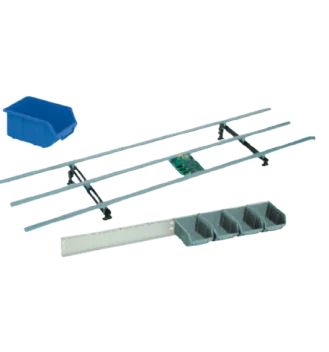

In this line the PCB is slided to the next operator after the components are inserted into the PCB by the preceding operator. The PCB slides into the slots of a pair of specially extruded aluminium channels. The width between the two channels is adjusted as per the width of the PCB.

Double sided operation. The PCB slides into the slots of a pair of specially extruded aluminium channels. The width between the two channels is adjusted as per the width of the PCB. The width adjustment is done on the stands provided, which are fixed on the work table.

The components are divided and distributed to the various operators working on the line. Each operator inserts his components given to him and slides the PCB to the next operator. At the end of the line, the PCB is fully loaded and ready for soldering.

The Line incorporates bin tray, for storage of components, Display board for fixing drawings / instructions etc and top lighting.