Manual PCB Insertion Channel FMC 350

This is a PCB mounting solution suitable for a start up or low volume production line. All the parts of the conveyor are provided for fixing onto a work table.

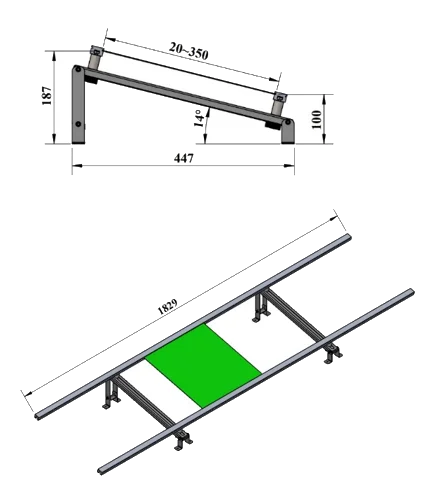

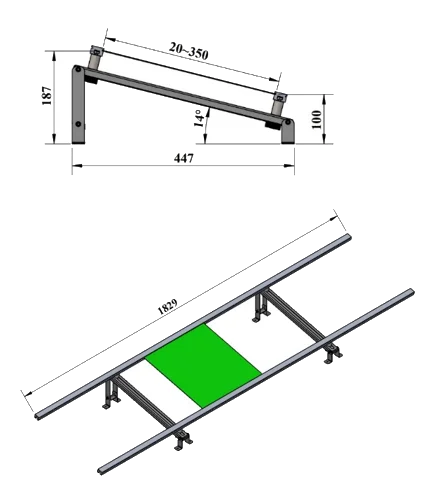

This PCB is slided to the next operator after the components are inserted into the PCB by the preceding operator. The PCB slides into the slots of a pair of specially extruded aluminium channels. The width between the two channels is adjusted as per the width of the PCB. The channels come in lengths of 1830 mm. They can be joined together length wise to form a complete line.