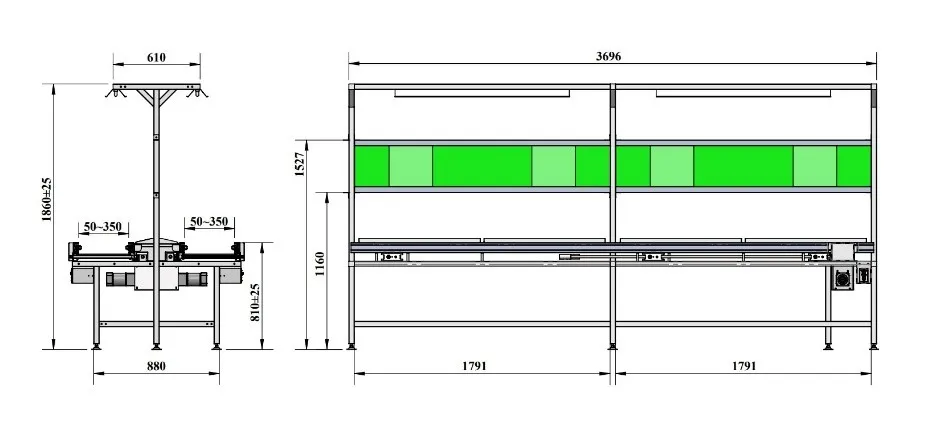

Motorised Double Sided MI Line

Double sided operation, with operators working on both sides. One side of the conveyor can directly transferring the PCB to the Wave soldering machine (finger type). And from the other side the PCB has to be manually fed into the wave machine or a shuttle conveyor can be used for transferring the output of both the lines to the wave soldering machine.

The operation is similar to that of the single sided MI line. The PCB moves on a chain conveyor, guided at its edges. On the moving conveyor, the operators insert the components.

The components are divided and distributed to the various operators working on the line. The operators sequentially insert the designated components into the respective locations. At the end of the line, all the components are inserted. And the board is ready for soldering.

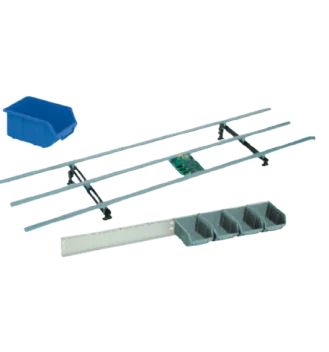

The PCB’s are guided at the edges and the channels of the conveyor are adjustable as per the width of the PCB.