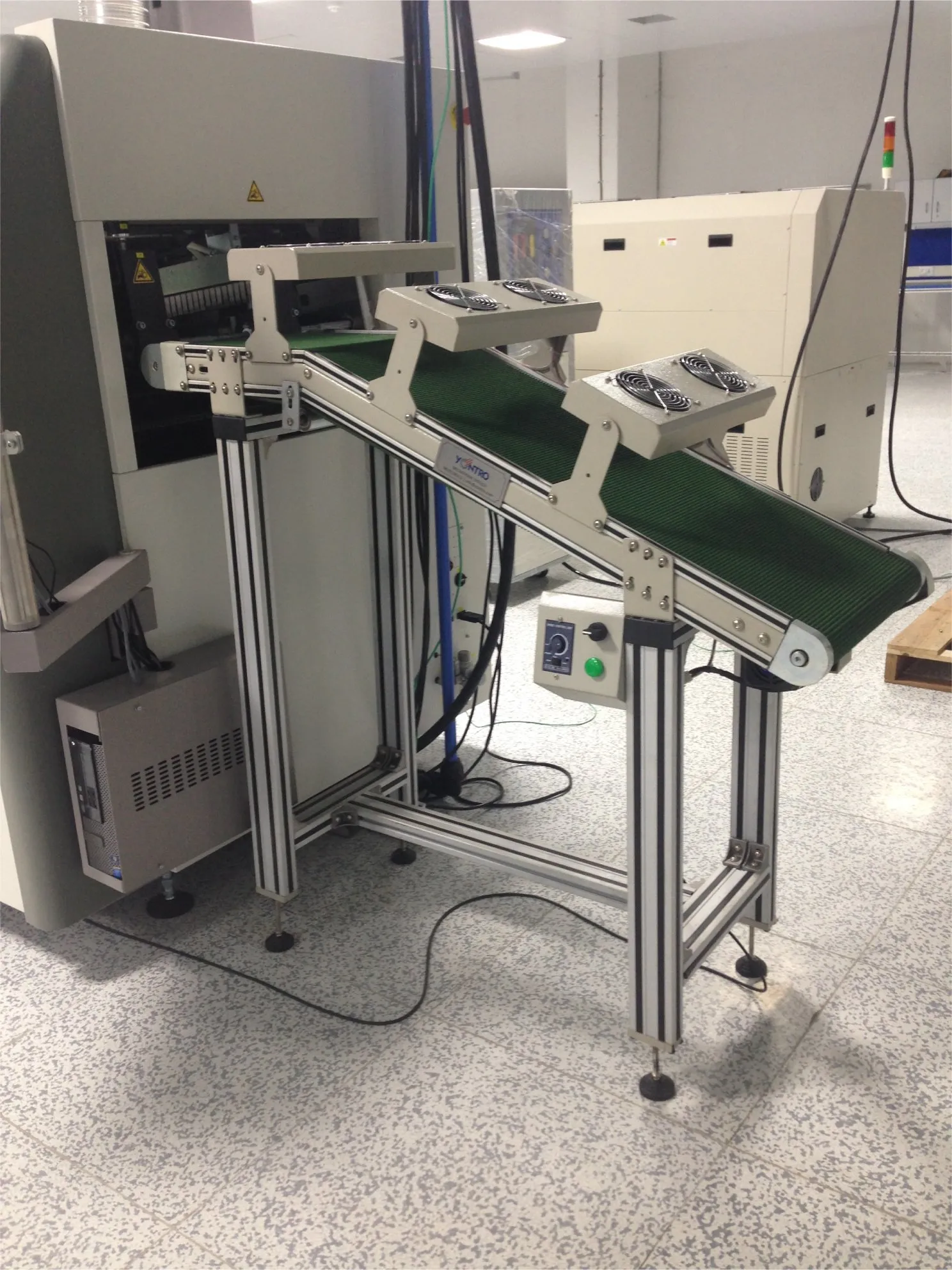

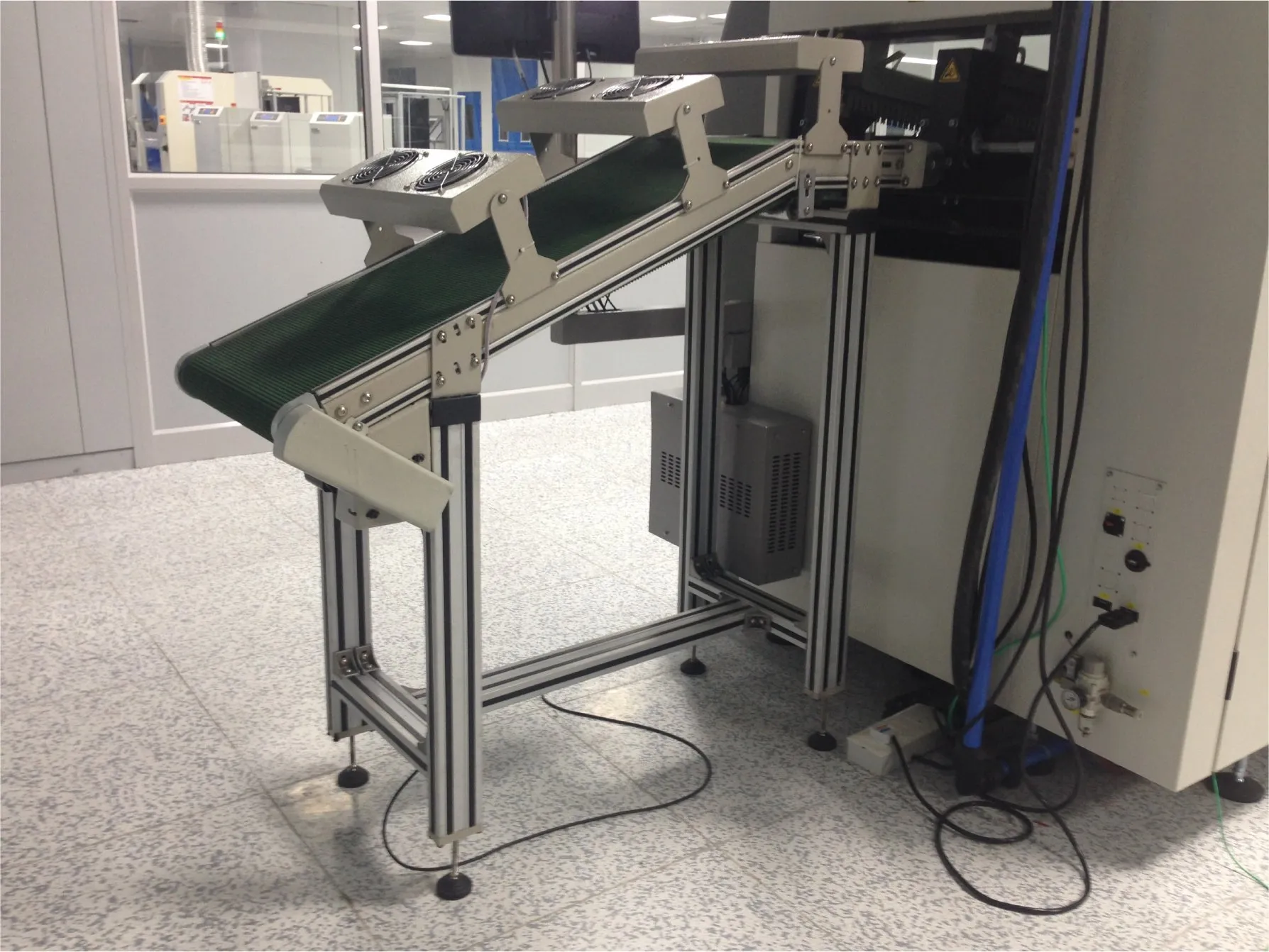

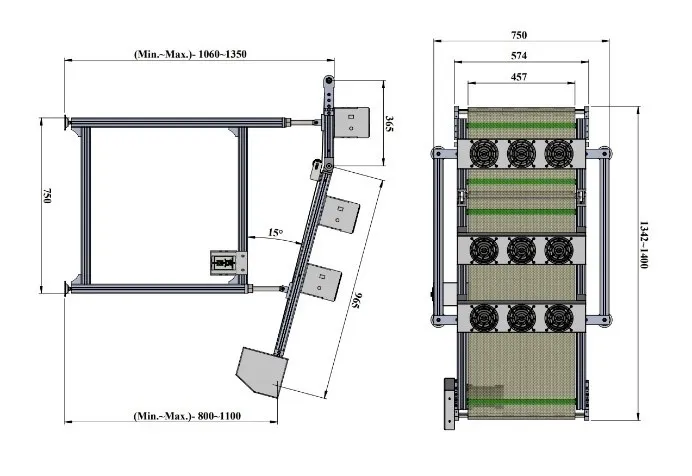

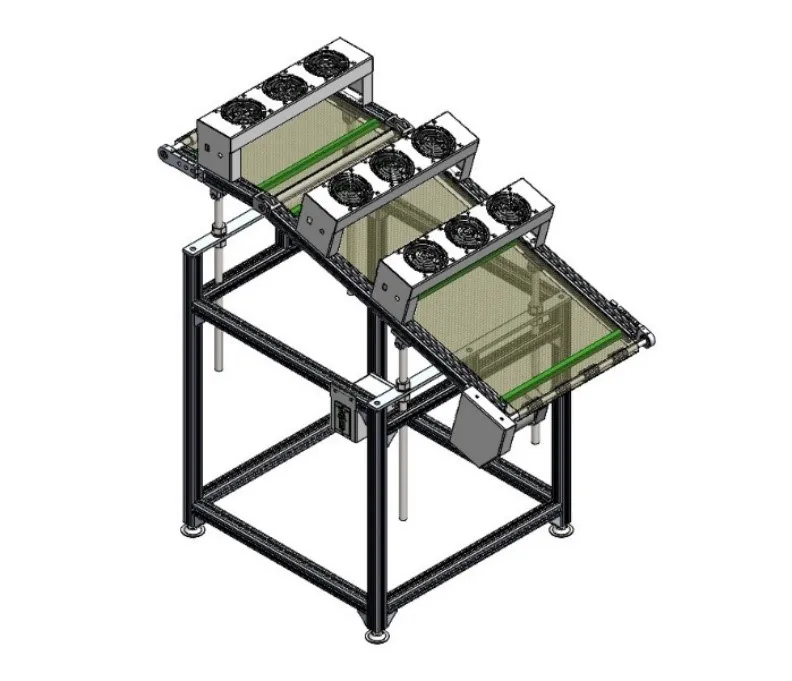

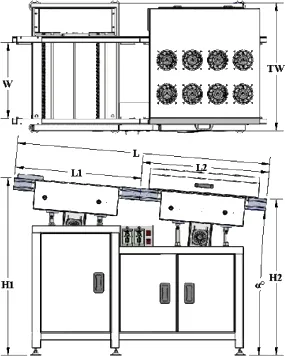

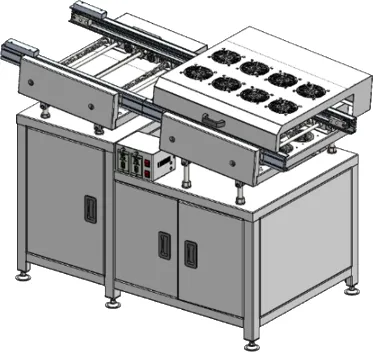

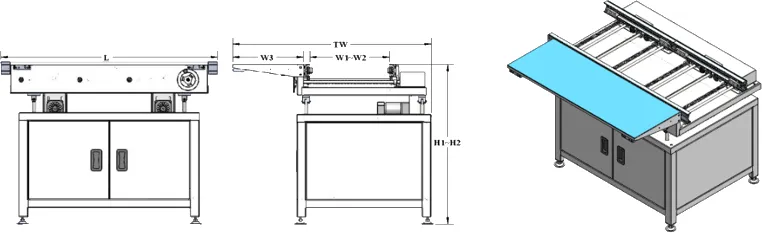

Output wave cooling conveyor anti-static PVC belt

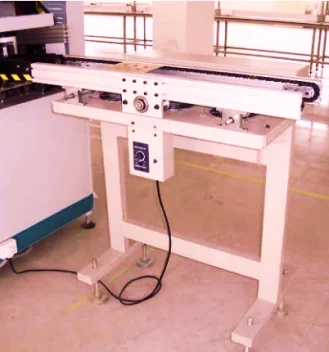

These conveyors are used for transferring PCB’s after soldering, from the Wave soldering machine to the Touch-up line. They incorporate cooling fans on top for cooling the PCB’s during transport. The belt used is an endless PVC Belt.

This conveyor is used to transfer the PCB after soldering at the output of the wave soldering machine, to the touch-up belt conveyor. The conveyor incorporates cooling fans at the top of the belt for cooling the PCB’s before transferring it to the touch-up conveyor. This facilitates easy handling of the PCB’s, thereby increasing efficiency and productivity.