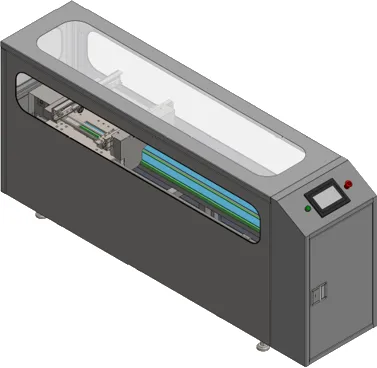

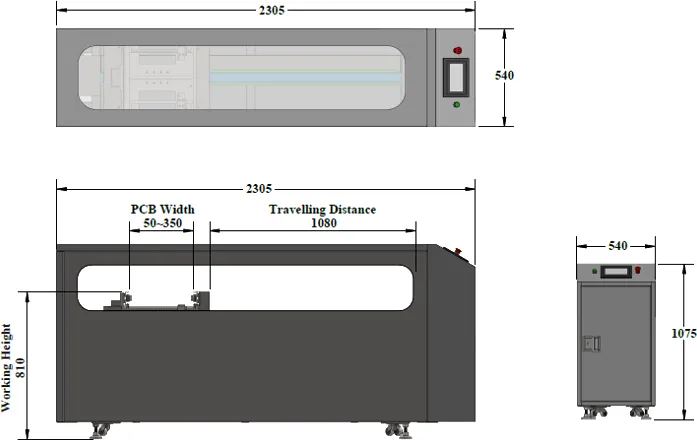

Shuttle Conveyor

Model: YMS-BH-SH-17060

For transporting the output from a dual track MI Line to input conveyor of the Finger type Wave Soldering Machine

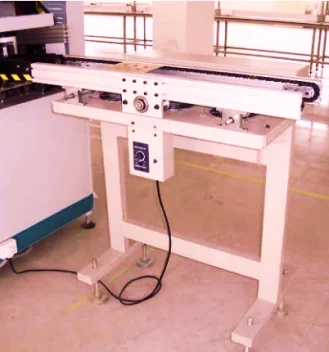

There is an increase in popularity of the dual sided MI line. At the output of the MI line, the PCB’s have to be fed into the wave soldering machine. One side of the MI line can be aligned with the wave soldering machine. But for the 2nd side, an operator is needed, for feeding the output of the 2nd line to the wave soldering machine.

To overcome this problem, we have designed the shuttle conveyor, by which the output of both the sides of the MI line are fed into the wave soldering machine. Through this, manual operation is avoided, thereby increasing efficiency and productivity

Similarly, for SMT machines, the output of two pick and place machines are fed onto the dual track reflow oven.