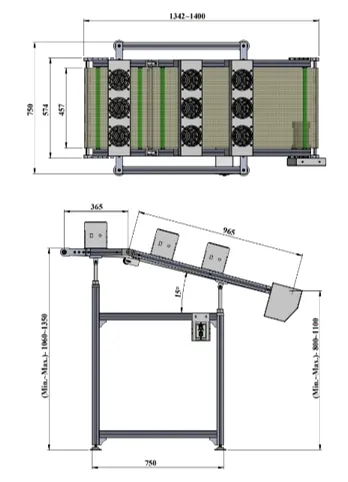

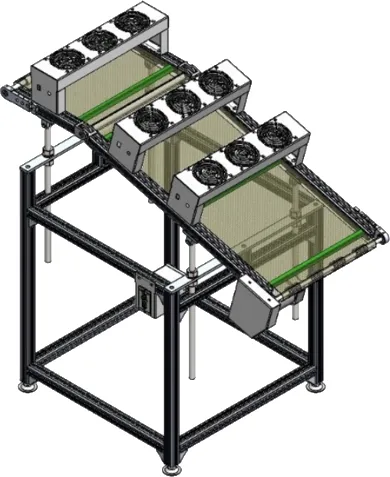

Output wave cooling conveyor - Mesh Belt

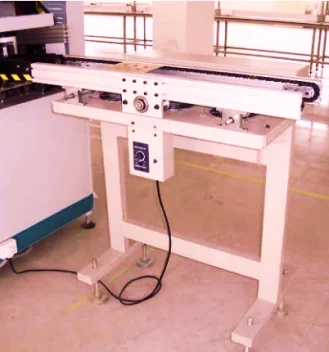

These conveyors are used for transferring PCB’s after soldering, from the Wave soldering machine to the Touch-up line. They incorporate cooling fans on top for cooling the PCB’s during transport. The belt used is a SS mesh belt.

This conveyor is used to transfer the PCB after soldering at the output of the wave soldering machine, to the touch-up belt conveyor. The conveyor incorporates cooling fans at the top of the belt for cooling the PCB’s before transferring it to the touch-up conveyor. This facilitates easy handling of the PCB’s, thereby increasing efficiency and productivity.

This conveyor incorporates a SS Mesh Belt for transporting the PCB, thereby ensuring a very long life of the belt, even while handling hot PCB’s.