Ageing & Soaking Conveyor for LED Lights

To ascertain the reliability of Electrical & Electronic goods, the products are kept switched on and in working mode for a certain period of time. During this process, the products are subjected to different voltages, surges, temperatures etc., to simulate the conditions at the actual working environment.

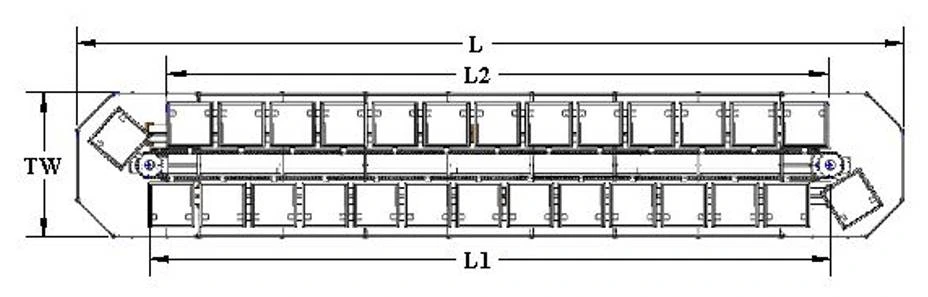

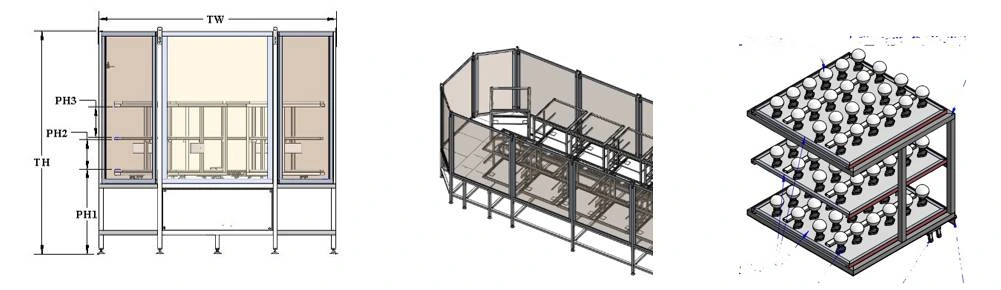

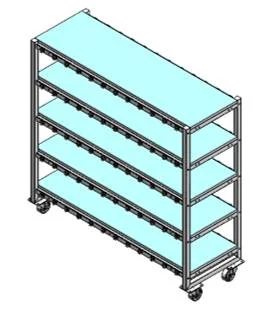

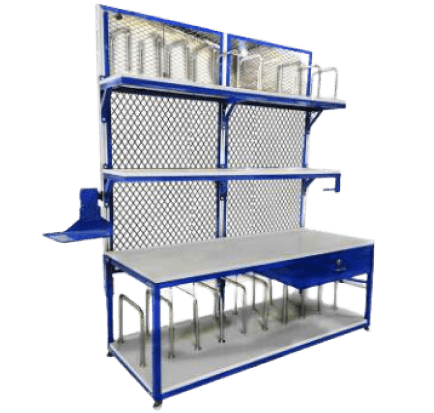

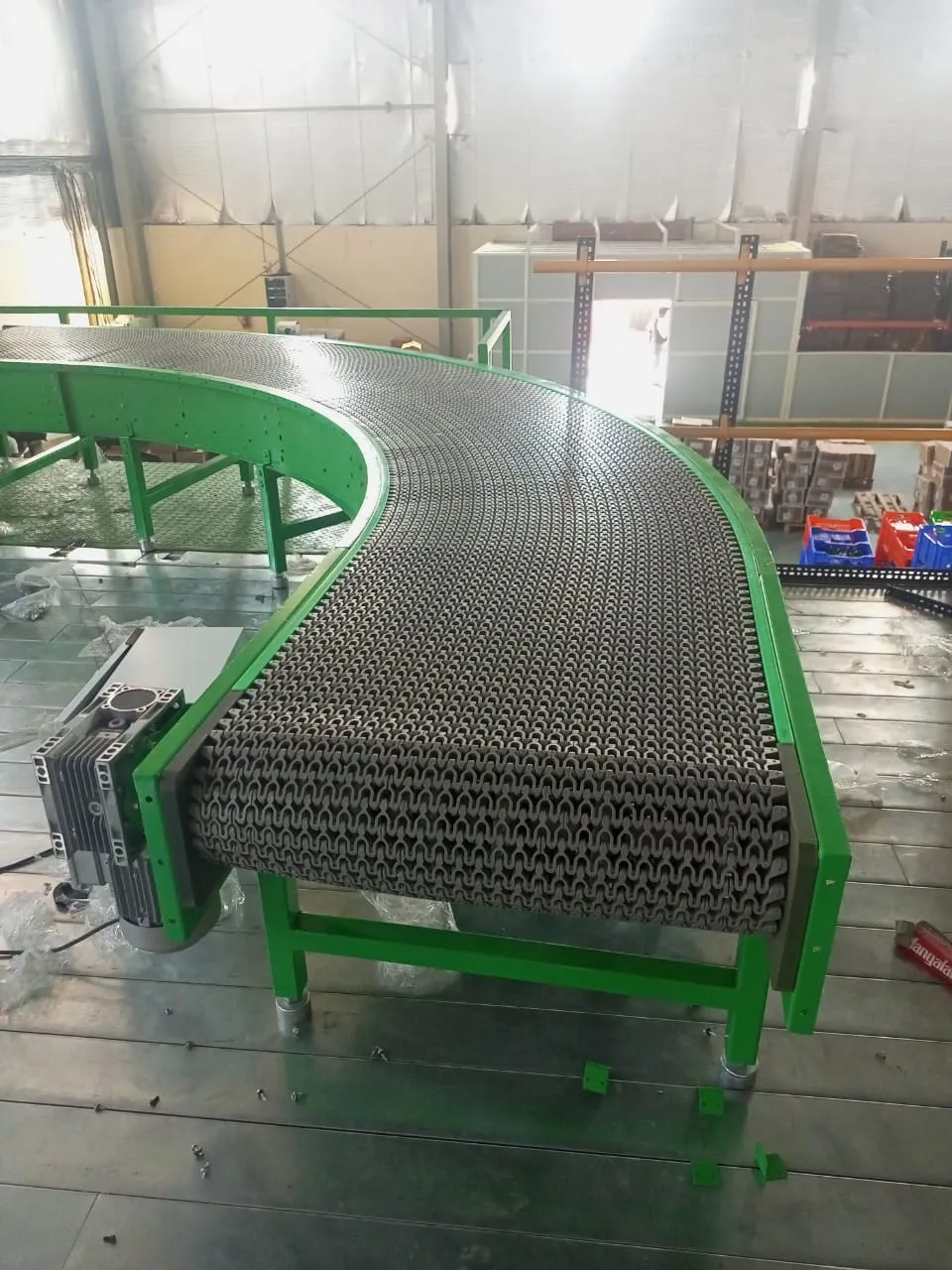

Ageing line conveyor consists of continuous running Conveyor System at fixed speed as per the ageing time/ Test time of each product, having continuous electrified bus bar with sockets as per product design which provide continuous electric supply to product.

These conveyors are designed to subject the product to the various voltage and temperature range, as per the specification of the product. And the speed of the conveyor is set, so as to, expose the product for the duration through which the product has to be tested.

This type of conveyor find application in LED light industry, white goods testing like TV’s, air coolers.

Aging or soaking conveyors play a crucial role in the manufacturing process by ensuring the reliability and longevity of the products. By subjecting the product to controlled conditions over a specified time. Manufacturers can identify and eliminate defective products, reducing the likelihood of failures once the products are in use. This process helps maintain product quality and customer satisfaction.