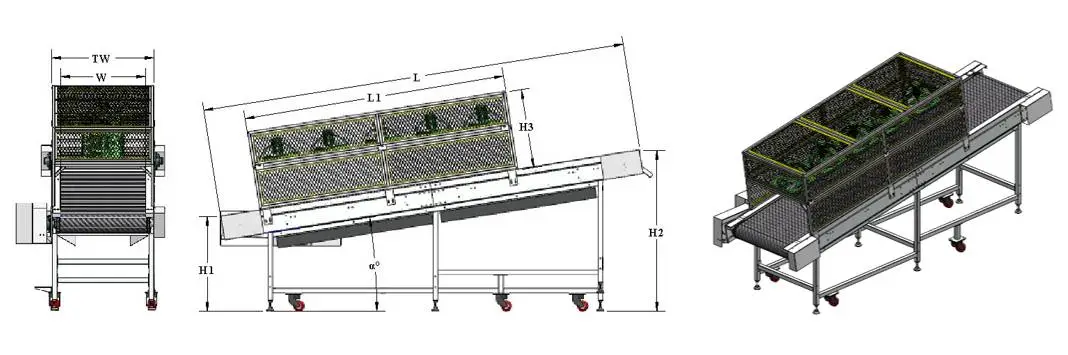

Cooling Conveyors

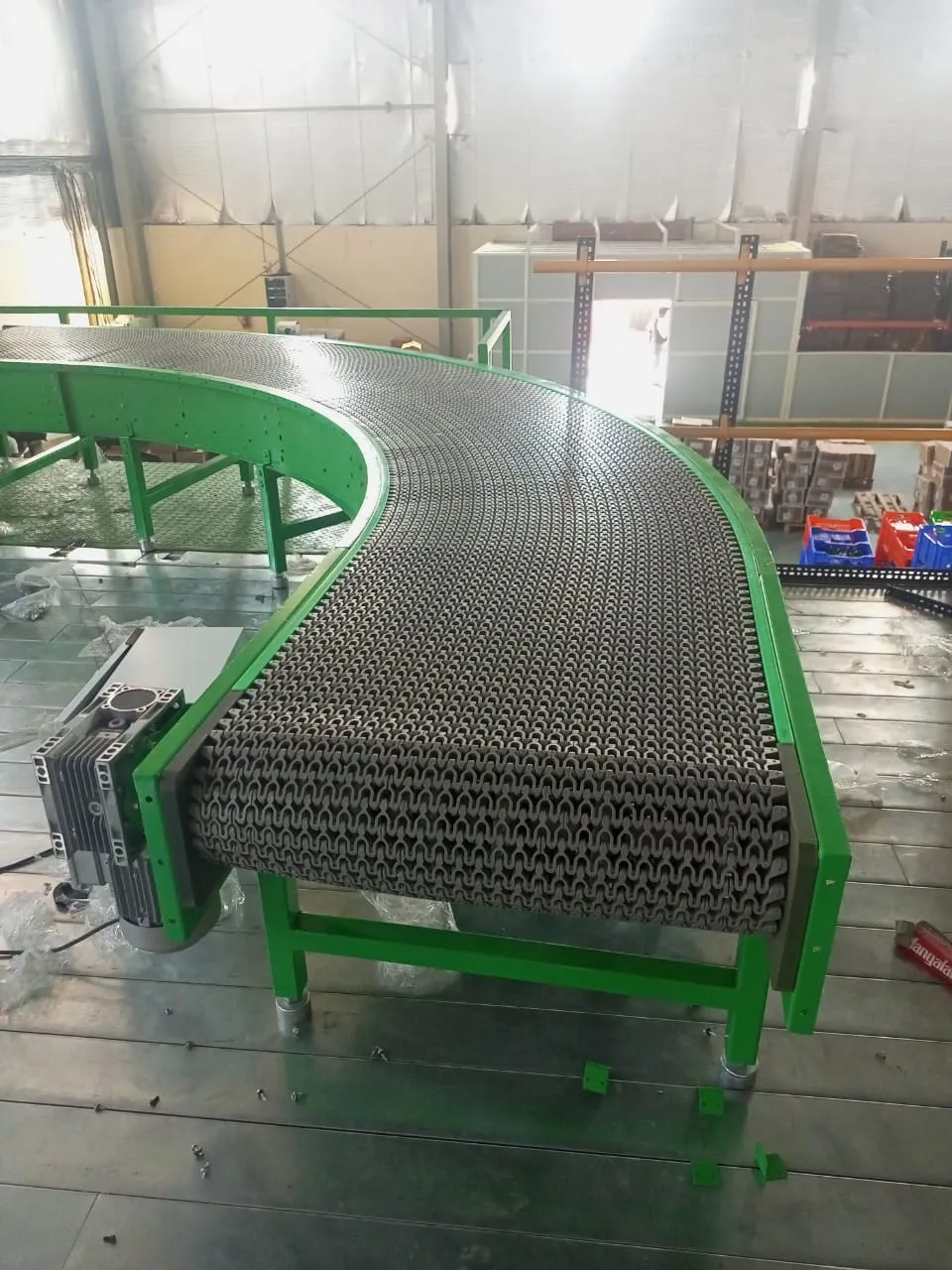

Cooling conveyors, also known as cooling tunnels or cooling lines, are specialized industrial conveyor systems designed to cool down and solidify products or materials that have been subjected to high-temperature processes.

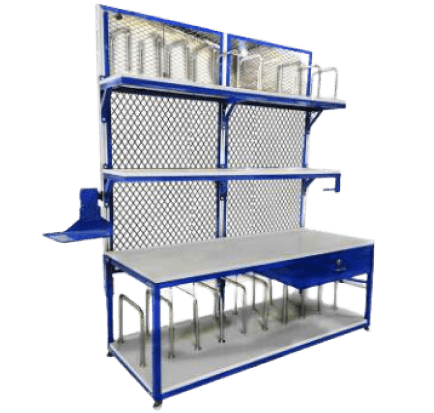

Depending upon the temperature of the product to be cooled, the type of belt is chosen. This type of conveyor can be made with PVC, PU coated, Wire mesh belt material or edge type chain conveyor.

Depending upon the rate of cooling required, the type of cooling method is applied. It may be normal air cooling, forced air cooled applied through blowers or fans, or through chilled air flow.