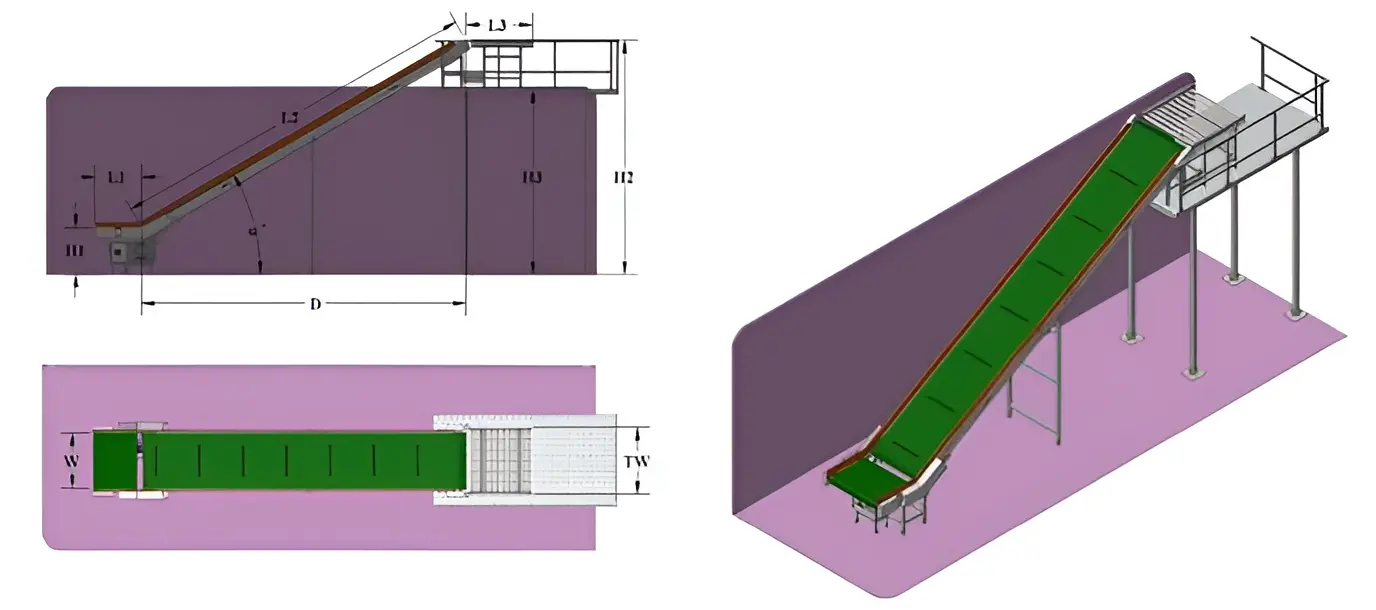

Inclined Conveyor

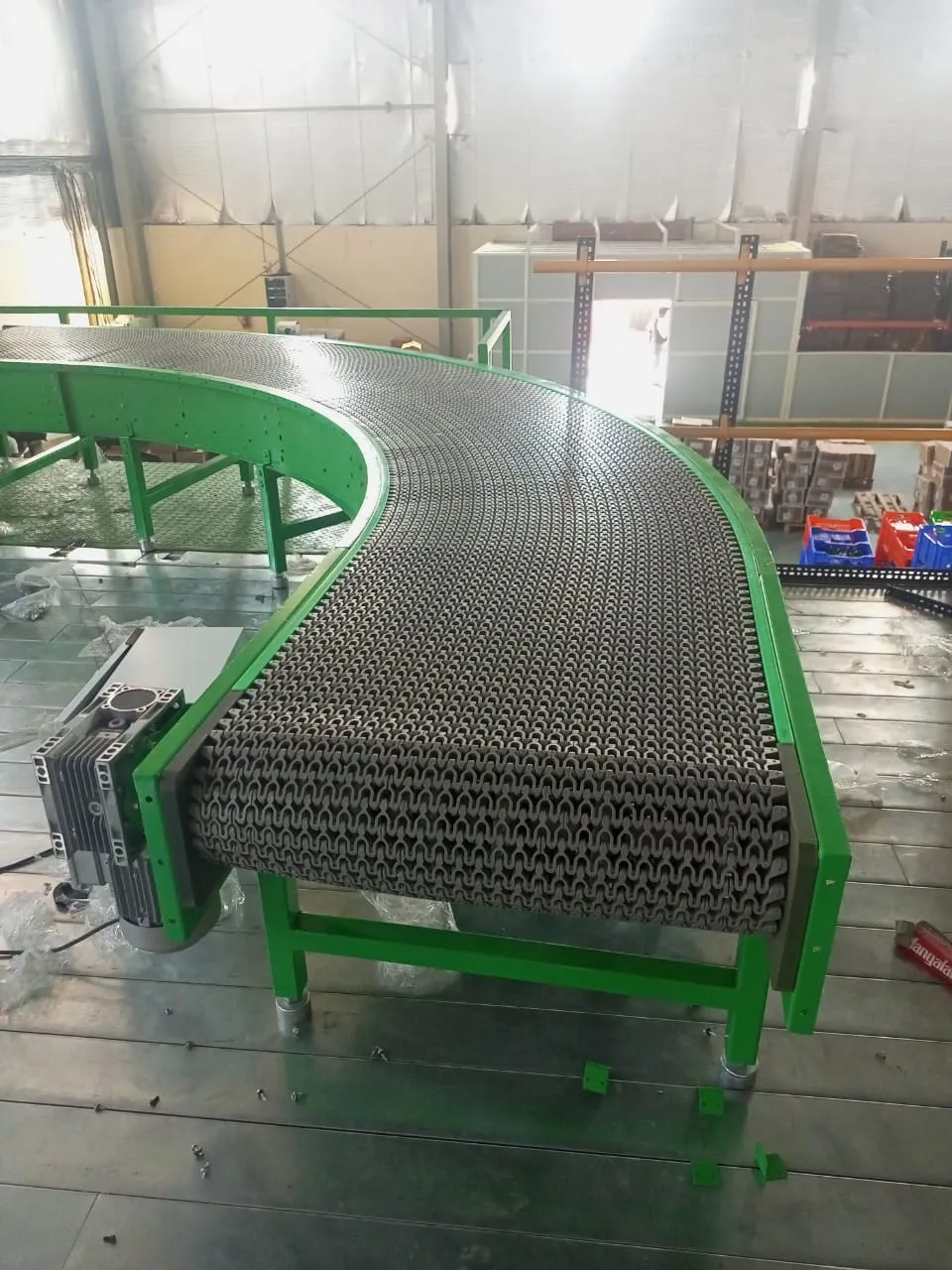

Belt (Plain & Cleated)

This type of conveyors are essentially used to transport material at different elevations. It can be used for moving products between two floors or loading and unloading trucks etc. For the various angle of incline or decline and the wight of the product, the selection of the type of belt is determined. As per the inclination angle, Plain belt, rough-top belt, cleated belt, modular plastic belt with cleats or drag chain conveyors are used.