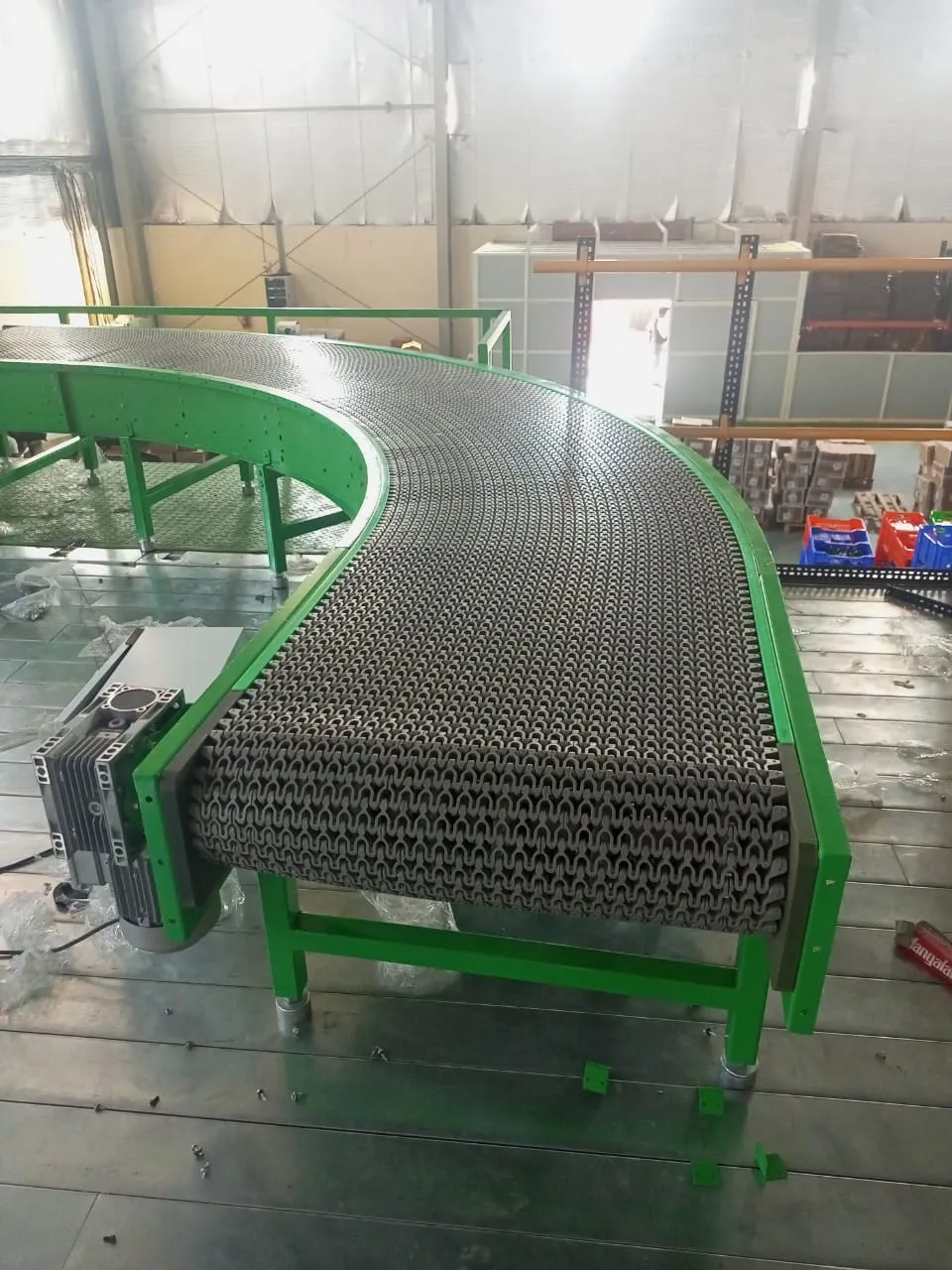

Roller conveyor

Roller Conveyors are ideally suited for moving products in a manufacturing line or warehouse, that otherwise may not be handled on a Belt Conveyor. Roller conveyors are extremely rugged and ideal for extreme handling. Various types of Roller Conveyors can be designed and implemented depending on the requirements.

One of the most commonly used roller conveyors is the Gravity Roller Conveyor - for economical non-powerized transfer of material. Such conveyors rely on the operator pushing the product on the conveyor - or - the product moving down an inclined conveyor due to gravity.

Powered Roller Conveyors are conveyors where the rollers are powered and power transmitted to each of the roller through a chain. This is ideal for moving heavy boxes and more demanding applications.

The Roller Conveyors can be custom designed in different lengths & widths. Roller type can also be customized to different diameters / special coatings depending on the application. Accessories such as sensors, speed control devices, pneumatic stoppers may be fixed on the conveyor as per requirement.