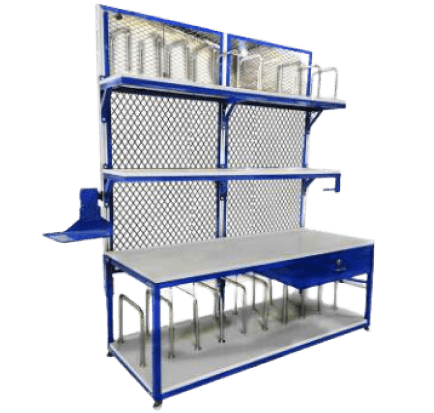

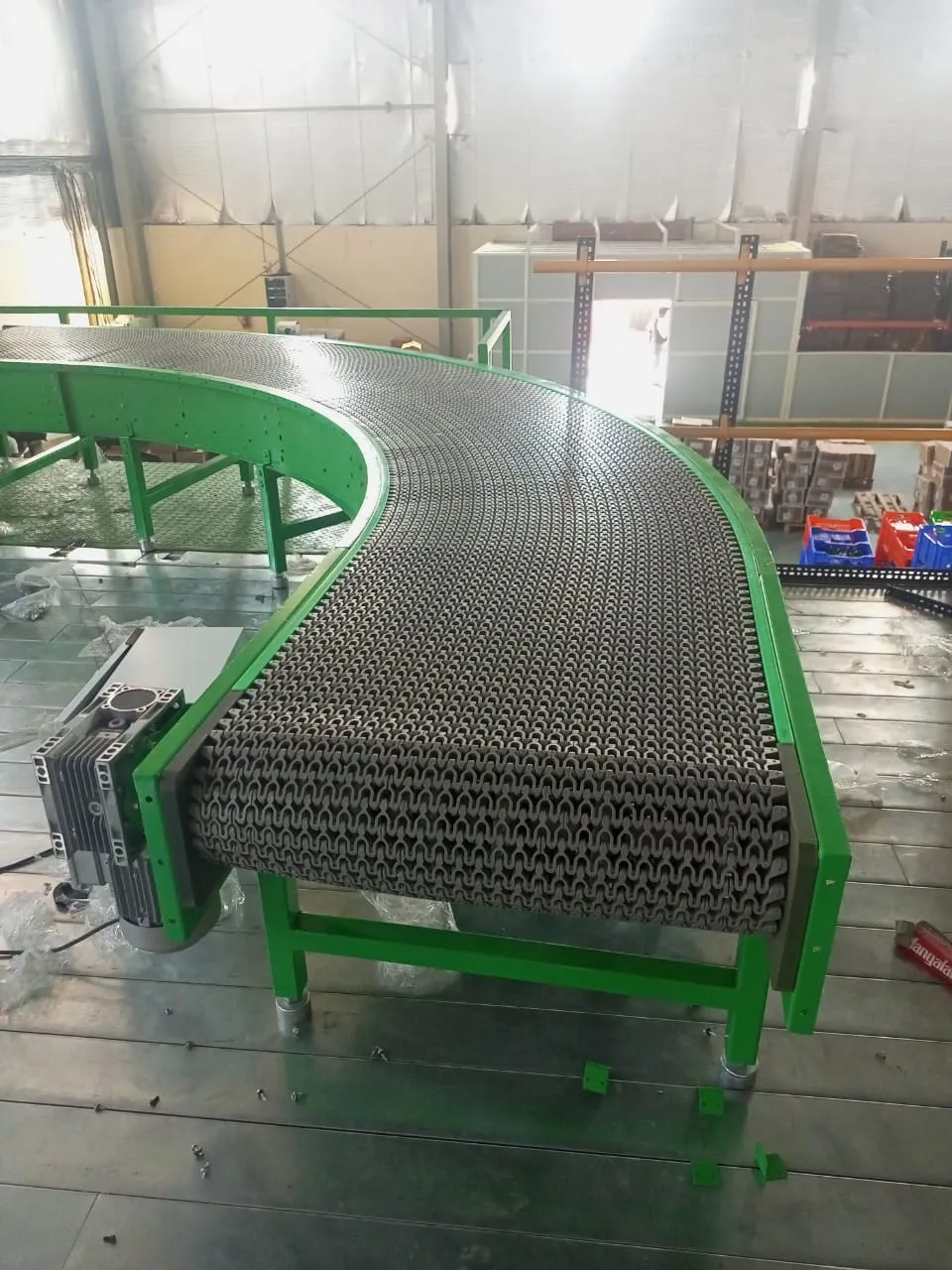

Free flow conveyor

Assembly Line For Heavy Sku’s (Sku Assembled on pallets)

Free flow / Pallet Conveyors are used to carry individual parts between assembly stations, machining centers and to other stations. The pallets are transported on a pair of track, with the pallet resting at its edges. The tracks are made of simple rollers mounted on channels, with the pallet moved manually by the operators or are built using endless chains running on aluminium profiles, on which the pallet is carried.

Each part is seated on a custom designed pallet, ensuring that the orientation of the part remains constant at all times. The pallets move on the conveyor asynchronously, and can buffer (or accumulate) prior to entering a workstation, or after exiting a workstation.

Various sensors and pneumatic stoppers are integrated as per the need, either through operators command or integrated with the control system that communicate with each station and ensure that the pallets are released just in time for the operator / automatic station to receive them.

Lifter stations and rotating stations can be incorporated within the conveyor line enabling the parts to be handled as per the custom requirement.