Vertical Conveyors

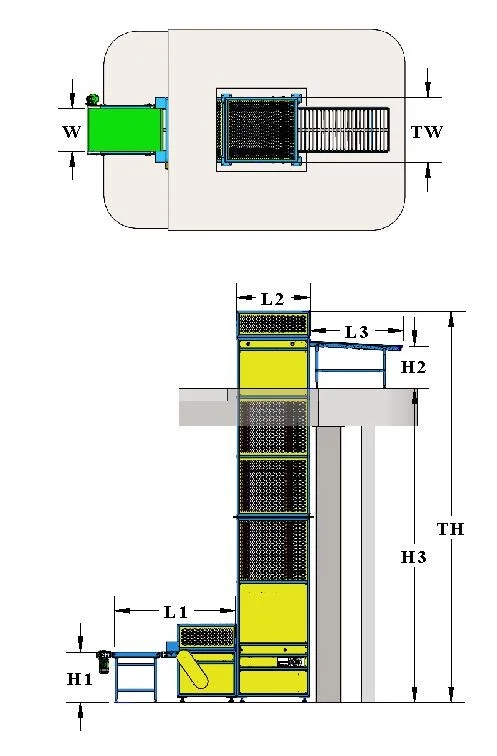

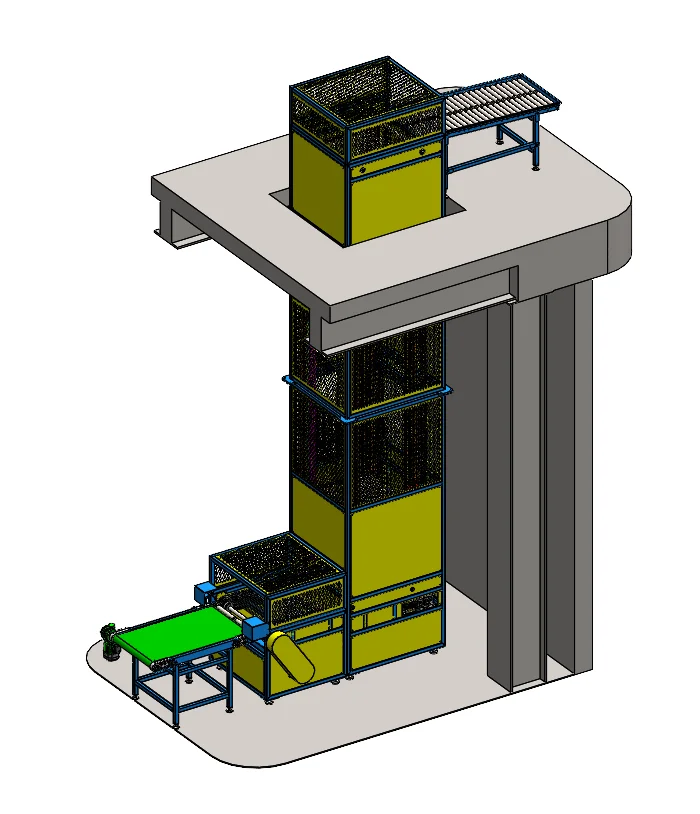

The continuous vertical conveyors is used to keep material moving continuously through vertical sections of the supply line. They accomplish this by implementing platforms, that originate from a horizontal conveyor, where these sections then move up a vertical shaft mechanically and then deposit back onto another horizontal conveyor of the same kind. They are easily controllable and have optional safety features and can be configured in C or S shapes (shown above in Figure 4). They take up a minimal footprint while still delivering a high capacity conveyor that keeps products in the horizontal orientation. They are widely used throughout industry to transport boxes, trays, totes, kegs, rims, tires, bags, and more.